Process design is as integral aspect in establishing a successful operation. Processes are a series of steps carried out in a specific order to achieve a specific outcome. The purpose of process design is to create processes that are efficient, effective, and aligned with the overall goals and objectives of the business.

Cyntek offers process design services for new and existing systems. Cyntek collaborates closely with our clients to understand existing process systems with the goal to identify and resolve inefficiencies and bottlenecks, resulting in increased operational efficiency and productivity.

At Cyntek, we understand the importance of clearly defining and communicating processes to our clients. That’s why we use process flow diagrams as a key tool in our work. Process flow diagrams are graphical representations of a business or manufacturing process that show the sequence of steps and the various components involved. They provide a clear and visual representation of a process, making it easy for our clients to understand and follow. This is particularly important when it comes to complex or technical processes, as the diagrams provide a simple and intuitive way to understand them.

Cyntek utilizes proprietary process models to generate a virtual representation of processes and to determine projected metrics related to the process performance and resource requirements. The process model is a form of value stream mapping which is a method for analyzing the current state of material and information flows for a specific process. Cyntek has the expertise to generate in-depth value stream maps that provide our clients with a digestible overview of their production process and enhance their ability to identify waste and increase process efficiency.

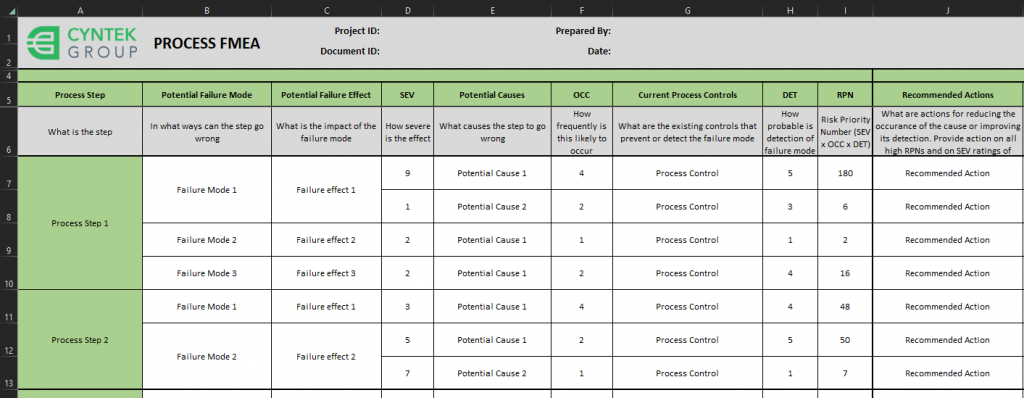

At the early stages of design, Cyntek will perform a failure mode & effects analysis to identify and eliminate potential process failures for the purpose of preventing an undesirable event. This step-by-step approach documenting failures and their consequences, as well as the frequency of failures and how easy failures are detected, with the purpose of taking actions to eliminate or reduce failures. An FMEA can also be used for analyzing failures of existing processes and can be used for continuous improvement initiatives.