By now most people in our industry have heard about a motor management program in some form or another, but what are they really and why do you need to know more about them?

As motor repair shops feel the pressure from existing and emerging threats in our industry commodity-level pricing is apparent when purchasing smaller motors. This drives down repair requests and the critical margin it provides. Developing new and innovative revenue streams is crucial in any businesses long-term success and CMMPs appear to be our industry’s answer. A CMMP strives to mitigate all factors that lead to client downtime in one turn-key service plan. Developing a CMMP offering will not only provide stable, consistent revenue but enhance your services range and separate you from competition. These solutions assist in securing long-term, operational-dependent relationships with our clients and becoming partners rather than just another supplier.

This paper aims to help you better understand the benefits of a comprehensive motor management program, how they work and the plentiful opportunities available for their application.

Overview

A comprehensive motor management program is typically a 3-year commitment consisting of the following foundation items:

- Understanding of the client’s needs, Goals

- Communication method, Team Structure

- Action Plan with Timelines

- Assumed or Actual Cost Savings

- Reporting Format, Software

Within this document we will study each of the above items to fully understand how each of these items contributes to a fully functioning motor management program.

Client Needs

While the clients vary widely in industry types and challenges, there are number of issues that are universal. These include reducing unplanned downtime, lowering service costs of the motor, improved services transparency, improvement of mean time between failures (MTBF) and finally, improving energy efficiencies in operations.

With electric motors and driven equipment accounting for 60%+ of plants electricity consumption, a proper motor management program helps reduce this direct overhead immensely.

Once deficiencies have been identified, objectives must be determined. This breaks down the CMMP into quantifiable steps, making the program easily measurable. Typical goals include maximizing motor reliability such as identifying and addressing over or under-powered operational units. A common second goal is reviewing efficiency of maintenance expenditures in plant operation. This step includes optimizing maintenance resources, consuming the maintenance budgets more effectively and improving quality of motor repairs. Another typical CMMP goal is assessing client inventory and recognizing irrelevant stock, as well as quality and levels of units available. Is the inventory managed properly and is it readily accessible? If not, how can we re-organize the workflow and storage to increase effectiveness?

It should be noted that each matrix item has a full description of the service or activity the program provides. These items are reviewed at the onset with the client, when setting up the customized program and this ensures each side fully understands the requirements and results necessary.

Communication

In a comprehensive motor management program there must be a strong channel of communication between the client and the supplier. Additionally, everyone is best served if there is a key point of contact on each side of the relationship to ensure all communication and activities are managed effectively and promptly as required.

This need for a strong communication plan is important from the initial meetings all the way through to project execution and daily onsite activities. Should it become a vast program with service personnel on site, the communication and reporting structure are even more critical to the success of the program. It is suggested that a Project Manager is appointed for both parties who also acts as the first point of contact.

A team structure is dependent on the size of the program and the number of assets intended to be managed and to what extent. Some programs may only require 1 or 2 people to gather data, compile and develop a program. Others programs, larger in size or complexity may require as many as to 10 to 12 people to manage and execute a successful program. We have found that with the option of a dedicated software program such as one developed by Siemens, CORE Systems and Baldor, the need for staff can be lessened.

Action Plan

The approach to realize the improvement potential of a CMMP can be broken down into three categories:

- Configuration

- Organization

- Operation

In Configuration, the objective is to evaluate the situation of a client operation and perform an audit of their rotating electrical apparatuses. This can include motors, pumps, gearboxes fans and blowers. During the audit we record all asset data electronically and any associated driven equipment. Next, identify the criticality of each asset in an operation and its condition. Photos are taken of each unit and upload to the chosen software platform, creating a real time database. A full inventory of all spares is also conducted with the same approach taken – all data recorded, pictures taken and uploaded.

In the Organization portion items include; conducting a full motor condition assessment, prioritize areas for improvement, fully implementing the management software, setting up on-site motor maintenance and completing a full inventory evaluation of all rotating apparatus.

Finally, in Operation, we look to fully launch the program and begin to work towards meeting the client’s needs and measurable goals put in place. This is achieved by performing a number of functions at once or in a preferred order that may include implementing Predictive and Preventative maintenance programs, organizing the motor storage area and rationalizing the inventory as required, start maintenance activities, implement motor management activities, perform Root Cause Failure Analysis on items where it is deemed necessary and continue to collect motor/equipment data and complete database for accurate tracking and information.

A timeline can be established of the tasks and the ownership of these items may be for the owner or the supplier or sometimes both. This can be as simple as a spreadsheet or as complex as a Microsoft Project Schedule updated to accurately reflect the scope and results.

Cost Savings

As with any service provided, there is a fee for performing a CMMP which is usually dependent on the number of units to manage as well as the scope of the program. This additional cost is considered when calculating CMMP return on investment (ROI) for the client.

The consolidation of asset information and identification of inefficient solutions throughout an operation are what generate the savings produced by a CMMP. A well-run CMMP can see a 30% improvement in motor reliability, 7-15% less downtime, a reduction of 30% motor inventory levels or 10-30% reduction in total motor maintenance costs. In order to convey these potential savings in meetings with prospective clients, it is easiest to present projections calculated with any preliminary data that the client can provide.

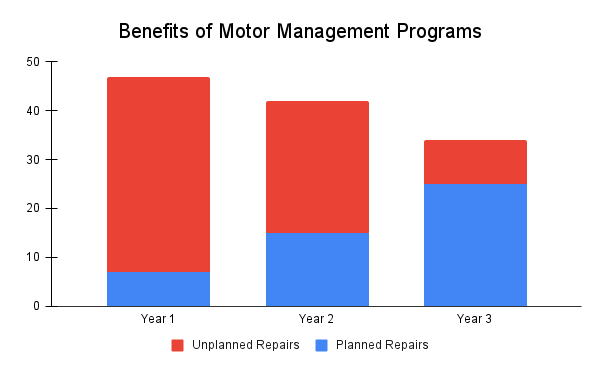

Figure 1: Graph of Repairs

Benefits of a Comprehensive Motor Management Program – Planned vs. Unplanned Repairs within a 3-year program

A monthly fee along with the cost of the individual repairs as required, will make up the expense portion of the program for the client. Specialized services such as Engineering or Capital Improvements are also separate costs but only utilized as required.

The cost savings will be realized from reduction of or realignment of staff and their burden, overhead of facilities dedicated to the repair of apparatus including equipment purchases and repairs, improved quality of repairs, improved quality and focused inventory and decreased downtime. Further cost savings are realized from improved efficiency motors replacing standard efficiency ones, improved PM and PdM services, Root Cause Failure Analysis and improved Application Engineering.

An example of the cost savings for a client with 1000 installed motors is as follows:

- Client estimates they have a 90% uptime in production of the classic Widget

- This is a 24-hour operation – widgets are in high demand

- This works out to 21.6 hours of production per day on average – leaving an average of 2.4 hours per day of downtime (A).

- If we assume that 1/3 (B) of this downtime is attributed to motor failures, we can then calculate 47.5 minutes of downtime per day due to motor issues. AxB=C (144 min x 33%= 47.5min)

- With the knowledge that the plant employs approximately 1000 people in production and the average wage, including burden is $50.00 per hour the average hourly cost per day to operate is $50,000.00 (D).

- The 47.5 minute breakdown works out to a cost of $39,583.33. D/60 = E (50,000 / 60 min = 833.33 $ per min)

E x C = F (833.33 x 47.5 min = 39,583.33)

- If we assume that during a breakdown only 10% of the workforce is affected in a particular area, the implied cost is $3,958.33 per day. Extend this over the course of a year at 350 days, the cost to the company is $1,385,415.50 in downtime.

- A fully implemented CMMP aims to improve uptime from approximately 90% to 95%.

- The 5% increase in uptime equals 1.2 hours of downtime per day versus the original 2.4 and translates to $692,997.20 in yearly downtime savings.

This same assumed cost savings structure can be applied when looking at the other type of savings discussed in this paper. These include inventory rationalization, monthly repair costs, and equipment and operations costs. Additionally, you can offer program participants cost savings for being a partner, based on volume or other criteria.

Once assumption based calculations have been completed, an overall cost savings projection can be presented in the discussion to execute a purchase order for the program.

Costs for the program for the motor repair shop are complex and require further discussion to fully appreciate and integrate into the overall monthly or yearly fee that is proposed to the client. Factors such as overhead costs, response and turnaround times required, software platform purchases and possible hardware upgrades may also be necessary. Additionally, of course the number of assets that are to be managed. This number dictates the hours required on site to manage and execute the various agreed upon services.

While it may seem that a monthly fee is challenging to overcome by the client, the cost savings they will realize and the physical benefits far outweigh their objections.

Reporting Format & Software

In order to be effective a CMMP revolves around a robust software platform. This provides proper reporting and even trend-identification which is critical to ensure that the work being performed is captured and reported clearly to the client.

It has been our experience that a seamless software program enables the users to input data as they perform the tasks of the CMMP, populating the database as items are completed. This data is then pushed into reporting forms automatically for monthly or quarterly reporting to the client. You can also have the reports accessible real time to the client so that the information is shared faster for better decision making. This level of reporting shows a large number of factors such as the amount of repairs or purchases in a given time period, any predictive or preventative maintenance activities performed, all spare inventory activity including shaft rotations and annual testing.

Complimenting the accessibility of the system, electronic tablets are used to perform tasks from the beginning audit all the way through to the motor repair on the bench and all points in between. This feature allows for better transparency in the work and ensures more accurate information throughout the process. This is achieved by the use of the real time input as well as pictures of repairs, completed units, installations and spare inventory.

The software is also used to compile reports for an individual asset which are then uploaded to that unique assets history. By making this information easily accessible and consumable, users are better informed when identifying recurring issues and making decisions overall. An example of these files are Root cause failure analysis reports, vibration analysis reports, surge test reports, balance reports, packing slips, or any other type of information that may be required by the user or client.

With the software in place and the database fully functioning, the user can:

- Customize the dashboard to show relevant information for the user.

- Minimize downtime with a single click for hot spare searches.

- Linked with the repair plants, initiate faster repair requests to repair shops.

- Track existing assets more effectively and manage them faster with fewer employees.

- Perform faster troubleshooting with full access to individual motor history.

- Clear cost-benefit analysis with repair cost and scheduled maintenance requirements information per motor.

Expectations

Short term results can be yielded from quick identification of major problems or other low-hanging fruit, however this program reaches its full potential 2 to 3 years from inception.

Within that time frame the cost benefit becomes more pronounced, the number of breakdown repairs decrease and downtime reduced. Initial 2 to 3-year CMMP contracts are typically succeeded by one year increments so the program is maintained unless the client wishes to take over the processes. The reality is that few ever do so successfully and quickly end up requesting support again.

Conclusion

While client’s needs are quite varied, due to size, location and demands, a truly comprehensive motor management program will ultimately benefit most any operation. As described in the above information, the program is customizable and with a proper management of the database, the end result is cost reduction due to much improved performance overall.

In an economy with lean manufacturing and a shrinking customer base, any opportunity to assist your client will benefit you and your business now and in the future.